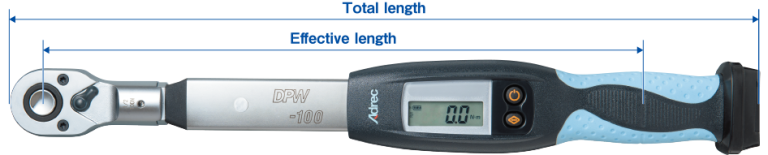

What is a digital torque wrench?

A digital torque wrench is a torque wrench that digitally displays the measured torque value on an LCD display. They are used for more precise torque control.

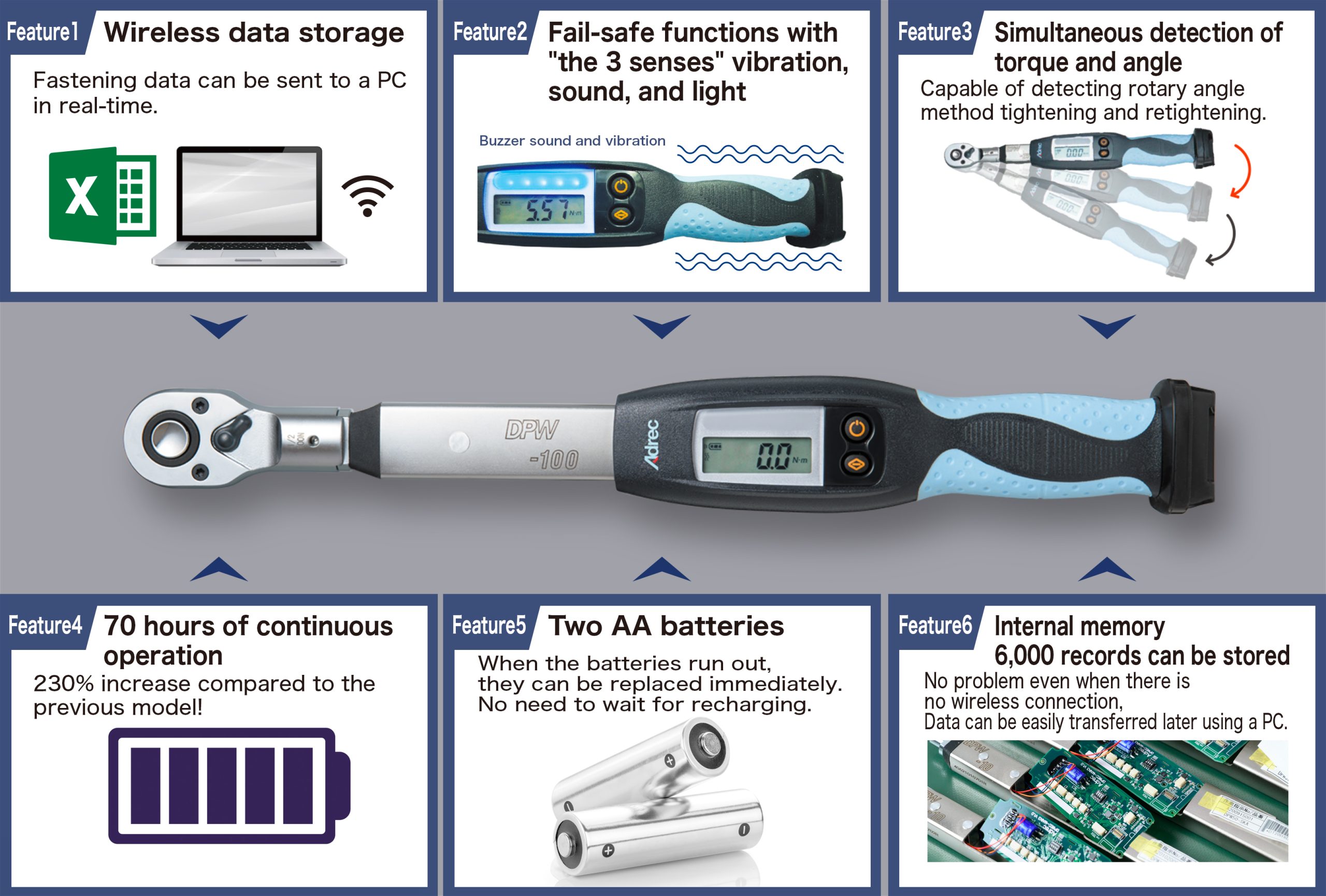

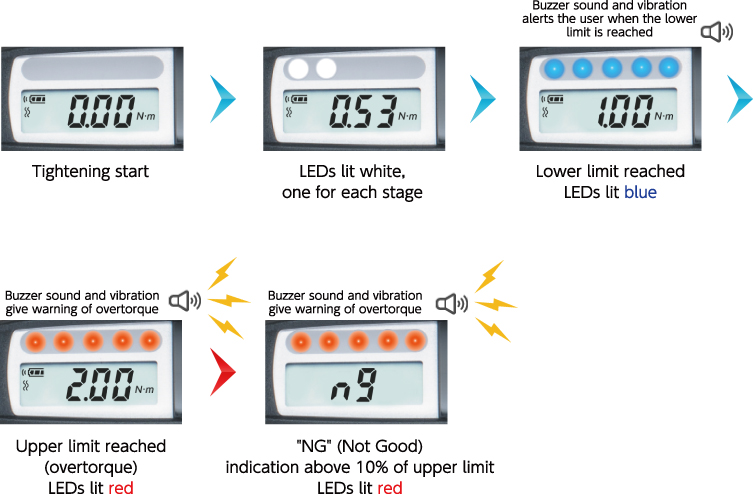

We provide products that simply measure torque values, and also products with fail-safe and operational support features such as setting a lower and upper torque limit, LEDs to indicate tightening status, and notifications and warnings with sounds and vibration.

When used on a production line, rather than using a digital torque wrench by itself, it is common to also wirelessly receive the tightening results on a computer, fail-safe controller or PLC, and go on to perform actions like storing the data, and linking it to a fail-safe system or production equipment.

Functions required of digital torque wrenches

Functions required by operators

・Assurance of tightening with the specified torque

・Notification when the specified torque is reached

・Automatic saving of the tightening results and simpler process of creating inspection sheets

・Reduction in time and effort of recharging

Functions required by production engineers

・Assurance that workers can perform tightening work with precise torque.

・Maintenance of constant quality.

・Incorporation of a system for preventing forgotten tighteners in the production line.

・Improvement in work efficiency by linking with various other production equipment.

・Automatic saving of work records, enabling traceability.

Functions required by design engineers

・Ability to measure torque values in real time.

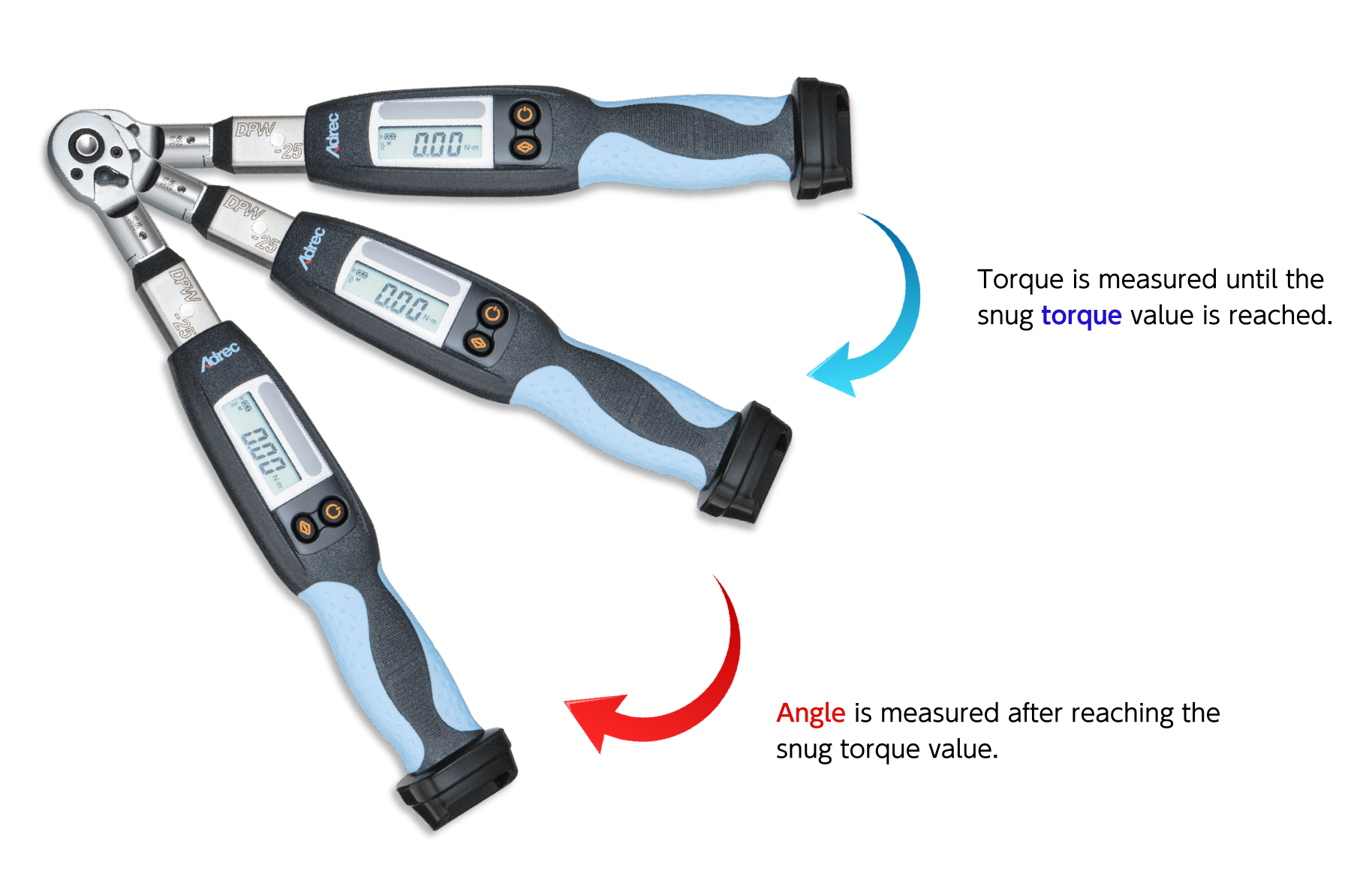

・Ability to measure torque and angle at the same time.

・Ability to graph the acquired data.

Features of Adrec's digital torque wrench "ProWrench"

ProWrench is a wireless digital torque wrench, developed by Adrec.

This is a next-generation digital torque wrench with features designed to improve production efficiency, such as precise torque value display, enhanced notification functions, and linking with PCs and other equipment.

Peak value detection

As the bolt is tightened, the peak torque value is received by PC software.

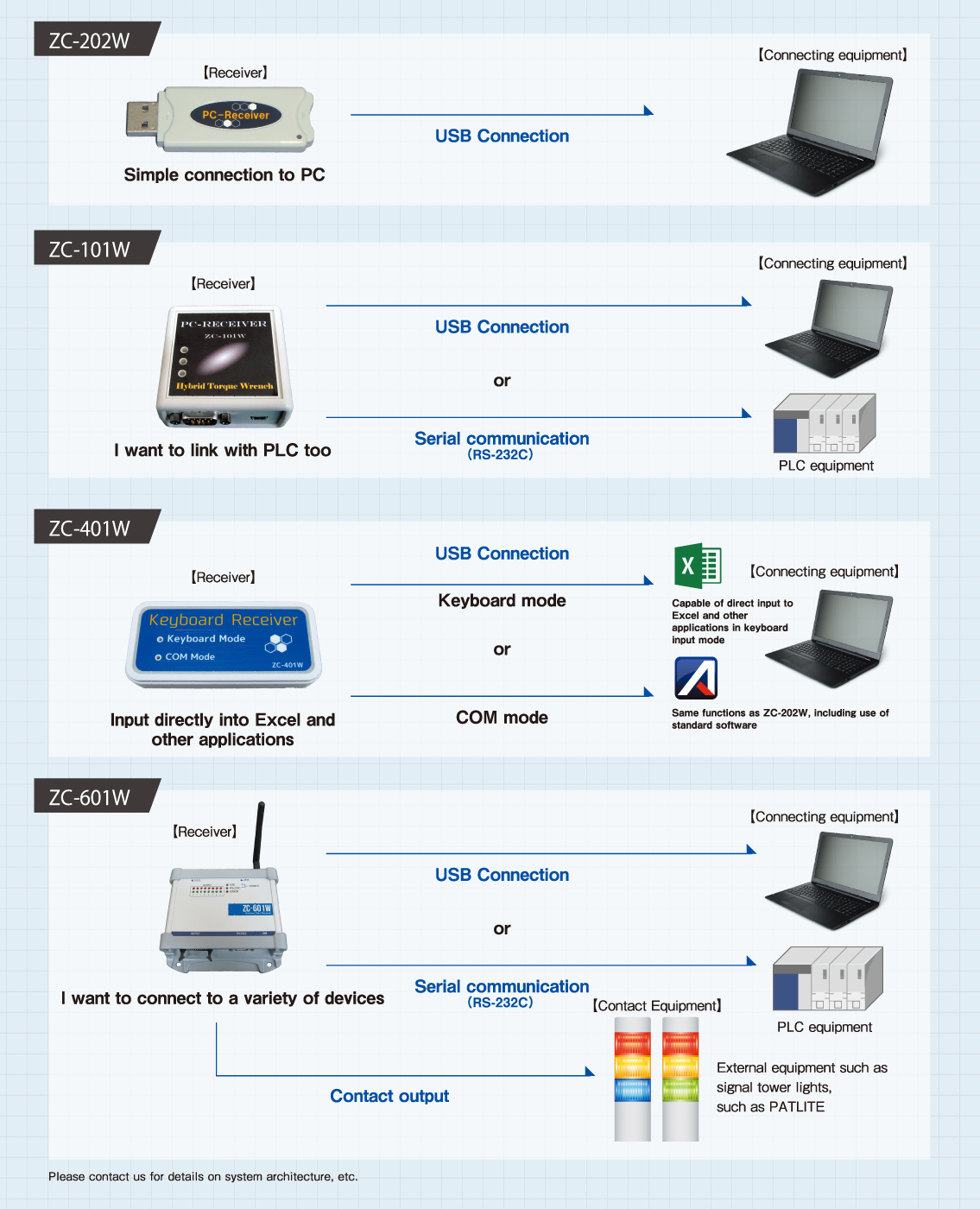

PLC Linking

The peak torque value is received by a PLC (sequencer). This can be performed with the "ZC-101W" receiver.

Linking with machine tools

The peak torque value is received by a PLC (sequencer). This can be performed with the "ZC-101W" receiver.

Advantages of using ProWrench for operators

Precise torque values at a glance

The exact torque value at the time of measurement is displayed on the LCD screen, so operators can see how much torque (N・m) is being applied to tightening now and how much that has actually been applied.

Notifications for the measured torque value through "light, sound, and vibration"

Lower and upper torque limits can be set.

When the measured torque value reaches the lower or upper torque limit, the operator is notified by buzzer, LED, and vibration.

With an analog torque wrench, a "click" sound is heard when the specified value is reached, but it is possible that overtorque can occur at that time.

Using digital torque wrenches, an upper torque limit can be set, so the operator can rest assured that the measured torque value exceeding the limit will be communicated to them.

Automatic saving of tightening results (no need to record by hand)

The torque value at the time of tightening can be automatically saved in the torque wrench unit itself, or transferred to a PC.

Using the saved data eliminates the need to manually enter torque values on assembly inspection sheets, and the like.

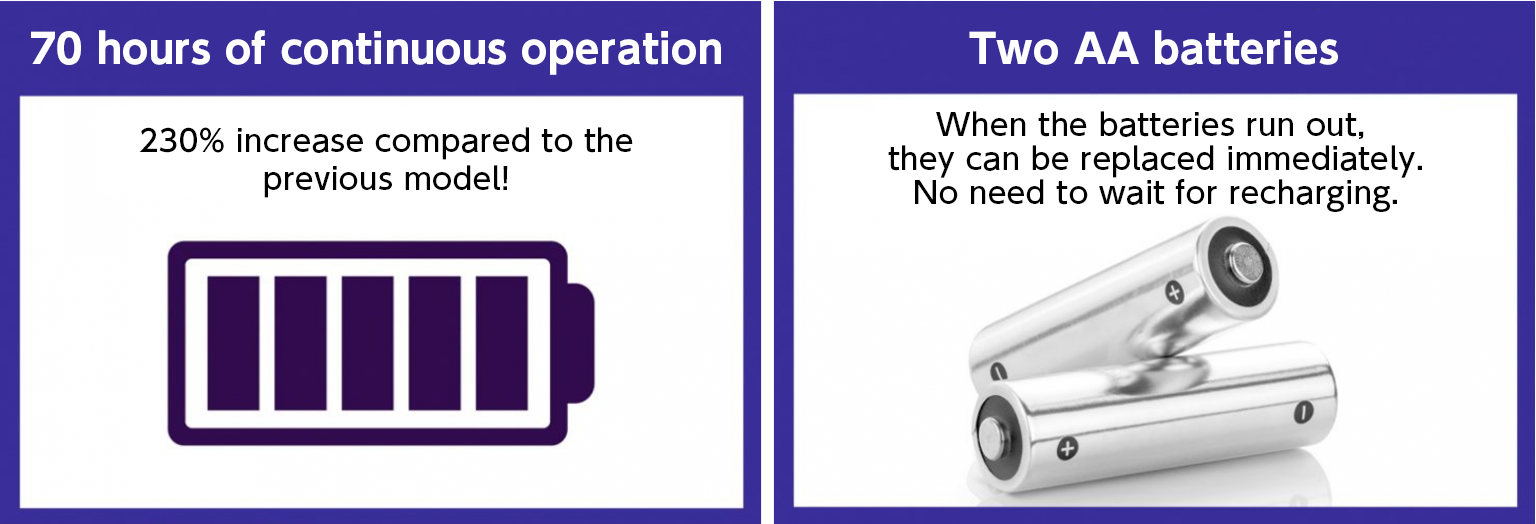

No need to worry about recharging (it uses dry cell batteries)

The unit runs on rechargable AA batteries.

If the batteries unexpectedly run out, work can be continued by replacing then with a charged batteries.

It's not like the case with lithium battery devices, where the unit cannot be used while being recharged.

Also, it can operate for 70 hours continuously on a single change so the batteries do not need to be recharged frequently.

Advantages of using Pro Wrench for production engineers

Ideal for fail-safes such as forgetting to tighten

The torque value can be notified through "sound, light, and vibration," and the retightening prevention function can be used to prevent retightening screws that have been tightened.

The dedicated software can also automatically set torque values for each process, preventing mistakes like selecting the wrong torque wrench to be used.

Various dedicated radio receivers enable linking with other production equipment (communication with PCs and PLCs is possible).

An wireless receiver can be used to link to a PC.

You can use our software to easily communicate with the torque wrench. Save the received data by using either the free standard software or by using class libraries.

It can also be connected to a PLC through various radios to link with existing production lines, or simply output 'OK' or 'Not Good' to a Patlite.

Automatic storage of work records eliminates recording errors

When working outdoors, the torque wrench unit can store 6,000 tightening results. Saved data can be easily retrieved on a PC using dedicated software.

When working indoors, data can be stored on a PC using a dedicated wireless receiver.

Using PLCs, it can also link with production lines.

Recorded data can be used for submission to customers, traceability, and for work analysis.

Advantages of using ProWrench for design engineers

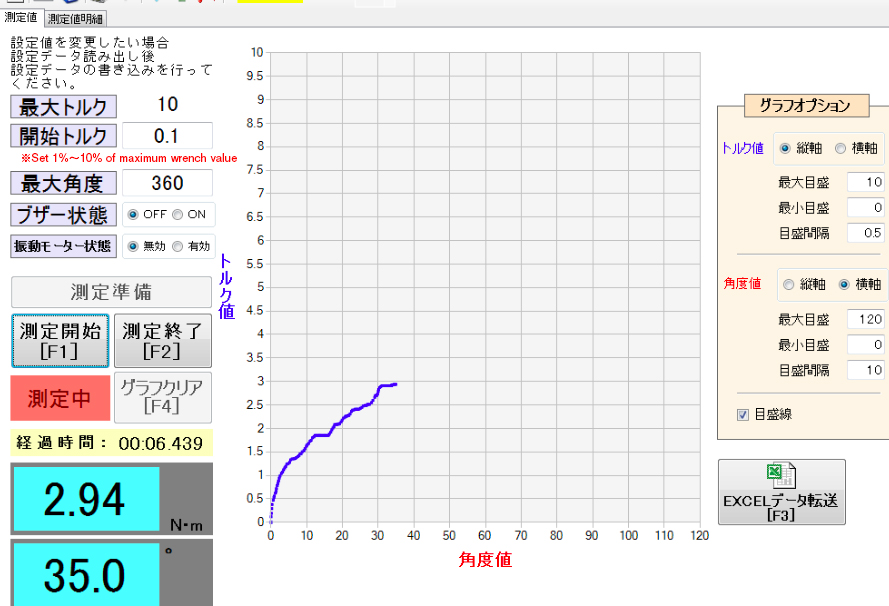

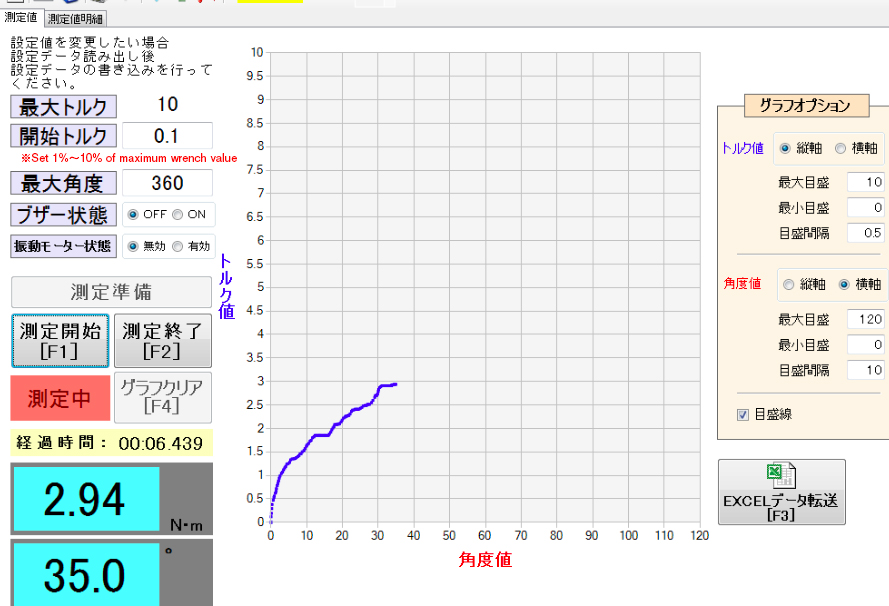

Measure torque and angle at the same time

Torque and angle can be measured simultaneously, making it possible to obtain detailed data such as how many degrees the bolt rotated before breaking, etc.

※Requires the activation of angle option.

This shows torque and angle data being received in real time and plotted on a graph.

Even more functions can be added by using dedicated software.

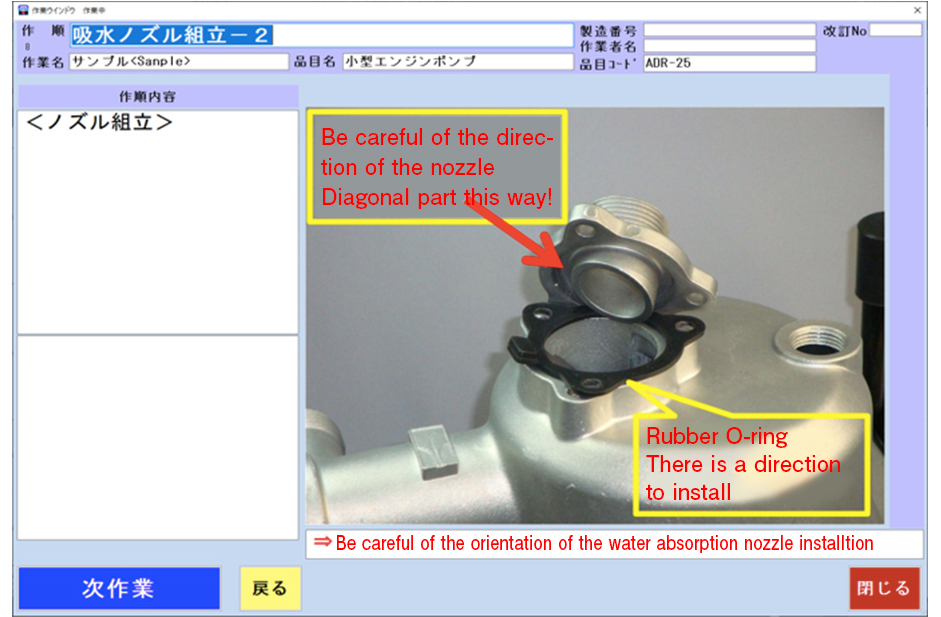

Enables work instructions through the display

With DigiproMaster, work procedures are shown on the display, and the operator simply follows them. When performing tightening work, the next operation in series cannot be started until after a set number of tightenings, thus eliminating the possibility of forgetting to tighten.

Automatic setting of specified torque values for each process

The torque wrench is automatically set with maximum torque set for each step in the process.

When using analog torque wrenches, it is necessary to prepare a torque wrench for each specified torque, but with digital torque wrenches, the number of torque wrenches can be reduced because the settings can be freely changed.

※Torque band setting ranges vary by model.

Automatic creation of inspection sheets

ProWrench can be linked with Mitutoyo's wireless measurement devices, and measurement results can be transferred to a PC to automatically create an inspection sheet.

This eliminates the need to manually record and input measurement results.

Free software

Torque management tool

Torque management tool for setting ProWrench, reading out data from ProWrench, or simple torque management.

Class library

Class library enables you to easily operate ProWrench from your own software.

Real time monitor

This software enables simultaneous measurement of torque and angle in real time. It is used for various experiments and verifications at development sites.

Even more advanced manufacturing support software "DigiProMaster"

Essential software for your digital transformation!

For customers for whom the free torque management tools are not enough, we offer a paid software package.

A manufacturing support and history management system with traceability management functions included.

Torque wrenches can be configured automatically to suit to each process.

The operator can just concentrate on the task at hand, not have to worry about the historical data that is automatically gathered.

If solutions for your compay's digital transformation are a priority, definitely consider this software.

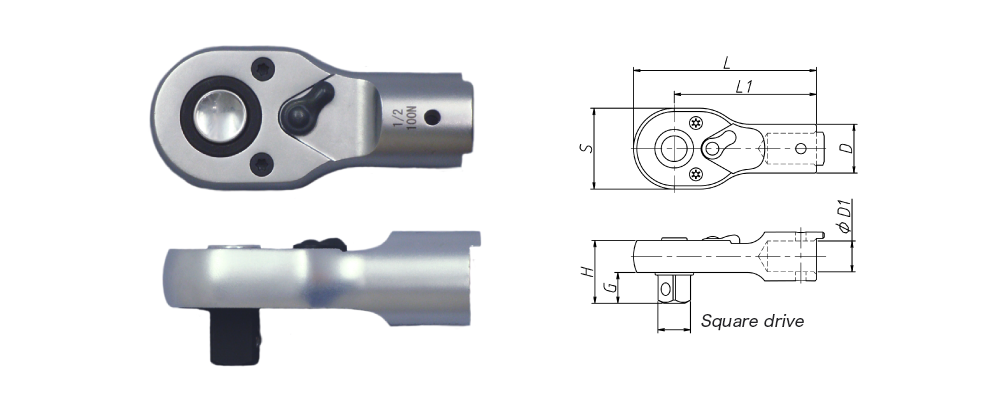

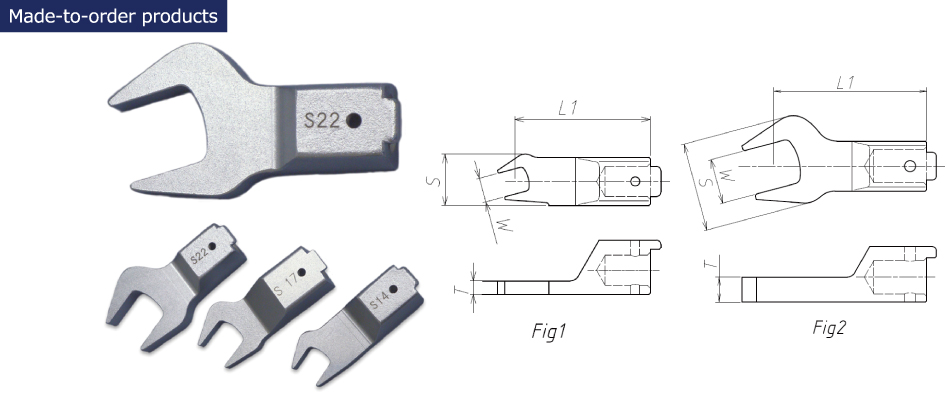

Product Specifications