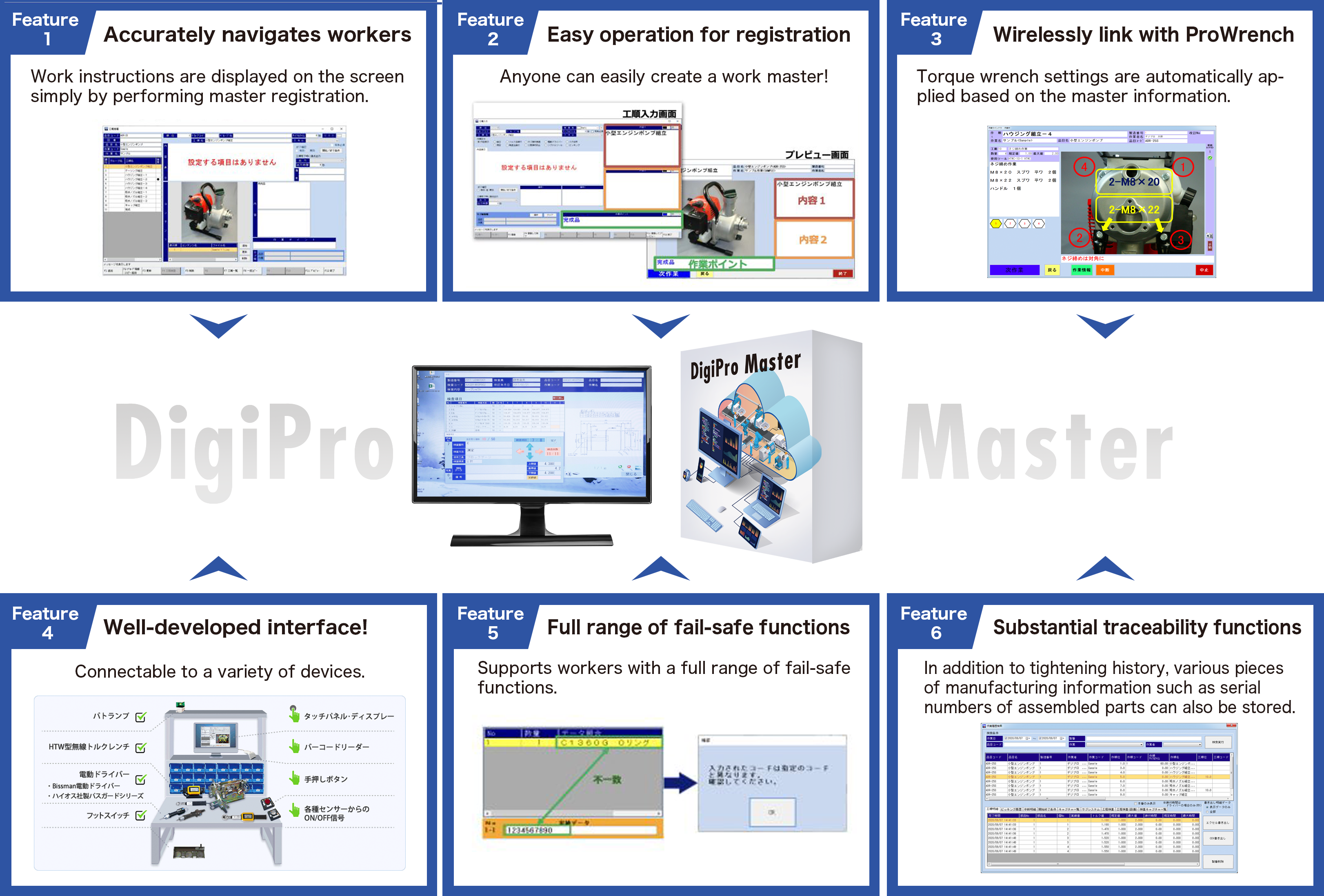

Supporting manufacturing from all angles

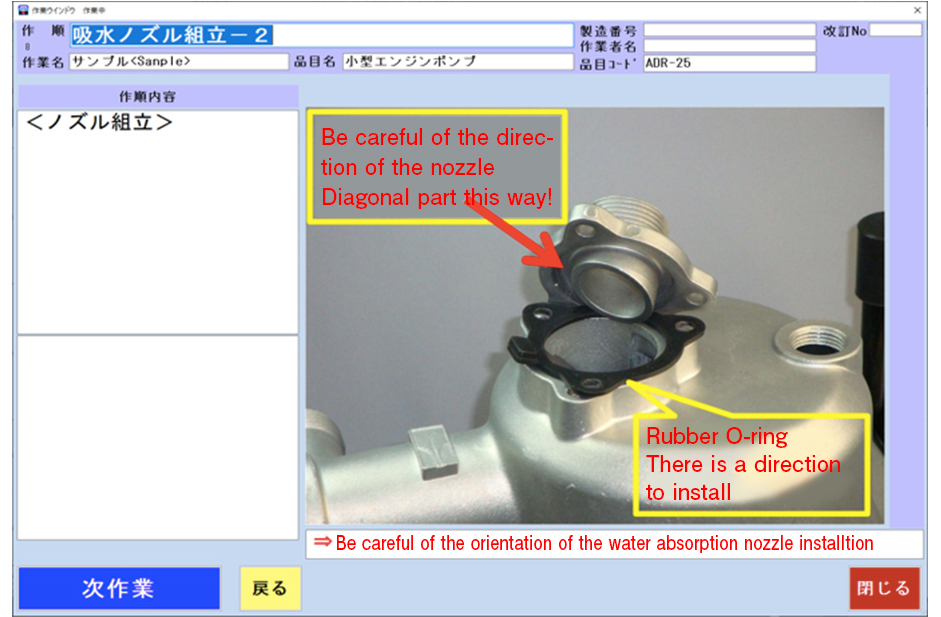

Work instructions are output to a monitor, master implementation with simple operation

The assembly procedure is registered as a master just like creating SOPs, so the operator can simply proceed with the work as displayed on the monitor.

If skilled techniques are also registered as a master, the quality of assembly can be standardized for anyone who performs the work.

A wide variety of data points are prepared, including the process work content and key points, the tools to be used, the number of tightening cycles, and the registration serial numbers of assembly parts, among others. Explanatory pictures and videos can be easily registered and used for work manuals for rookies.

With the SOP option, master information can also be imported into the company's own SOP Excel files.

Dramatically improved assembly work efficiency by linking with ProWrench

Conventional assembly sites require a large number of analog torque wrenches set to specified torque values. By linking ProWrench with DigiPro, the settings can be changed anywhere within the valid ranges, dramatically reducing the number of torque wrenches required.

Moreover, since the torque settings are implemented by the DigiPro, the operator can concentrate on the tightening work without even worrying about them.

It also acts as an effective fail-safe because it will not allow proceeding to the next operation until it receives the specified torque values for a set number of tightening cycles. Furthermore, the optional "Retightening prevention" feature of the ProWrench also defends against forgetting to tighten screws.

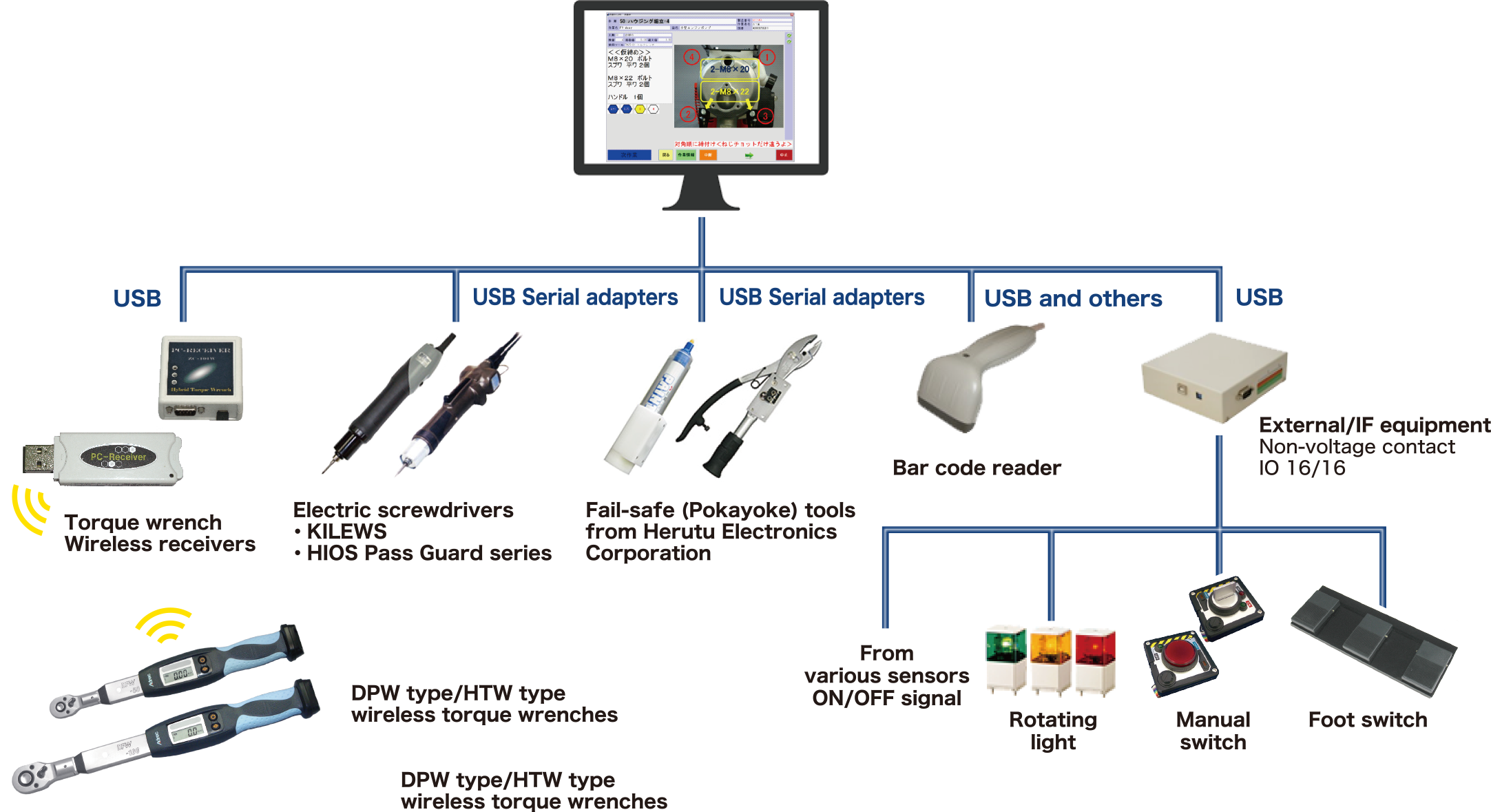

Full-featured interface!

Link with measuring instruments and tools from other manufacturers!

- Compatible with bar code readers as well as ProWrench.

- Supports up to 16 I/O points each, through other external IF devices.

- Both manual hand and foot switches can be used to operate the work screen

- The work screen can also be controlled with other inputs.

(e.g., can proceed to the next work screen when a completion signal from the tester is received, etc.)

Link with some third-party measuring instruments and tools.

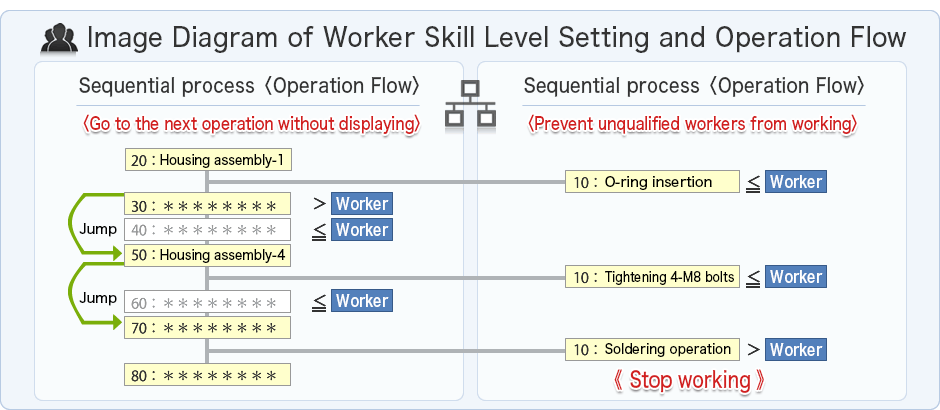

Navigation according to the operator's proficiency level.

Work screens can be skipped depending on the skill level of the operator.

However, processes that keep a history, such as tightening work and inputting the serial numbers of assembled parts, cannot be skipped, so there is no need to worry about work omissions.

The system can be used safely by users of all skill levels.

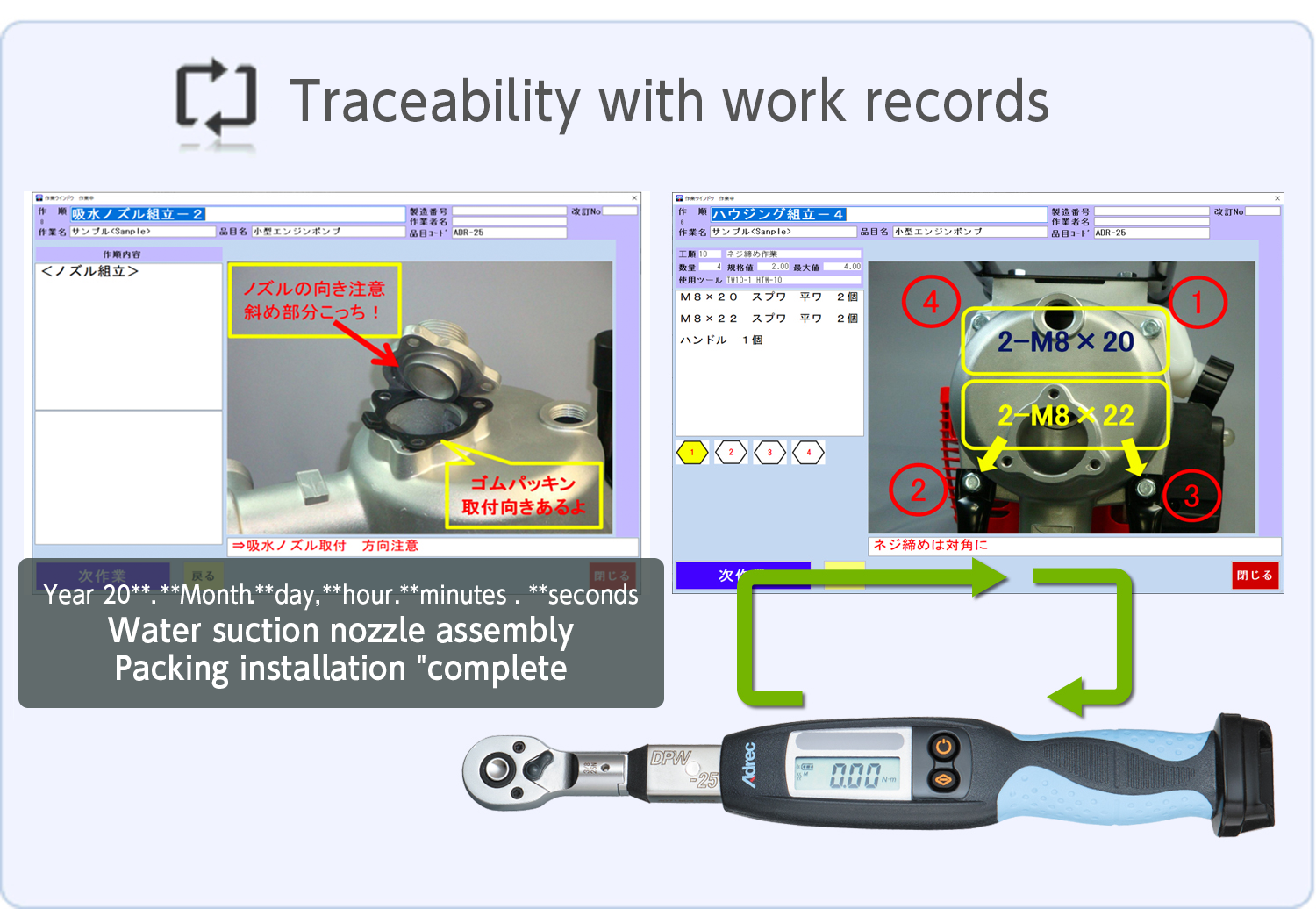

Enhanced traceability management

The system is designed to keep a history by simply entering a serial number and proceeding with the work. What used to be done on paper is now be easily digitized. Below is an example of a history.

- Working Date & Time

- Interruption time, contents

- Results of bolt tightening and other measurements taken by measurement equipment

- Various tool completion signals (torque-up signals, etc.)

- Part serial numbers

- In-process inspection results (OK, NG, actual values)

- Name of worker who double-checked

- Part picking history (when linked to picking system)

4 options available!

DigiPro Inspection

Supports "In-process inspection", "completion inspection" and "equipment inspection" linked with DigiproMaster.

Easily digitize checklists and the like that were previously filled out by hand.

DigiPro Standard Operating Procedures

The work procedure information registered in the DigiProMaster can be dropped into the company's SOP Excel files.

It simplifies the creation of SOPs.

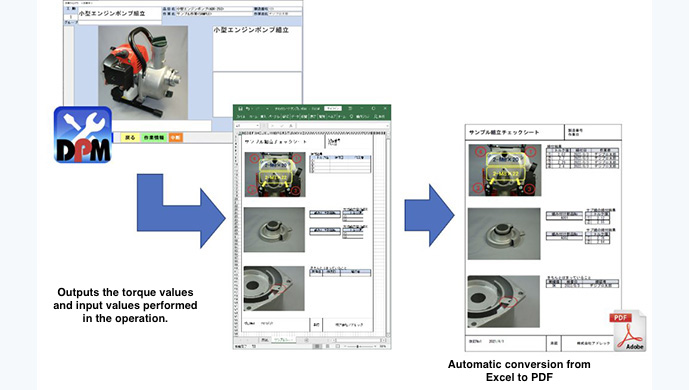

DigiPro Check Sheet

This function will output the results of work and process inspections performed in DigiProMaster to a specified Excel file cell (or object), which will then be converted to a PDF file for output. With this function, a check sheet can be created with a single click after work is completed.

DigiPro Analysis

Historical information collected by DigiProMaster can be easily aggregated.

It can be used to improve operations.

Over 150 licenses|DigiProMaster can be purchased on its own!

DigiProMaster can be used without measurement tools or equipment.

Even if the operator changes, the work procedure can be registered in the DigiProMaster to provide a lecture or sorts on the work in the form of an electronic manual.

Please consult with us before purchasing!

Many companies have already adopted our products and are using them in a wide variety of ways.

Please contact us first and we will create the optimal proposal for your company.

Online consultations are also available.